Precise and fully automatic

Performance:

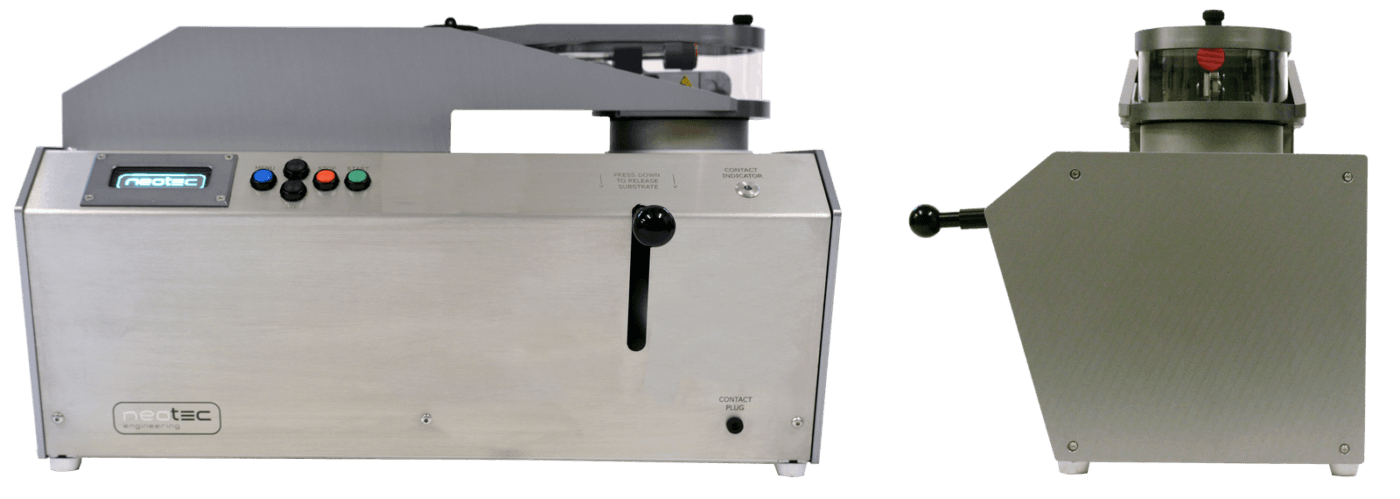

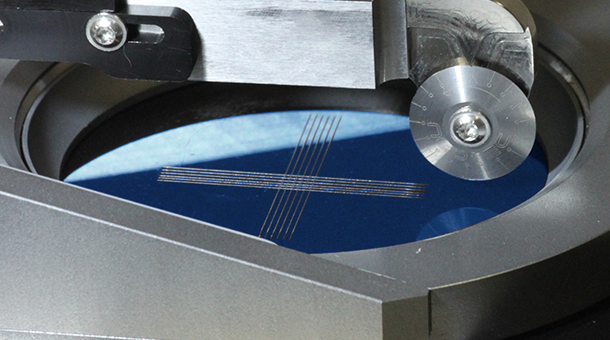

– Fully automatic pattern cutting and panel rotation.

– Eliminate operator variations.

– Precise and reliable operation.

Accessibility and operation:

– Panels can easily be positioned or repositioned for cutting multiple patterns per panel.

– Wide range of substrate sizes and materials are possible.

– Fast, efficient, easy and silent operation.

– Easy cutting blade force adjustment.

Proven concept:

– Similar system has been in use by renowned companies for almost 20 years.

– The CHC2 is a robust instrument, made with high-quality components.

Safe, yet fast

Risk reduction:

– Avoid safety issues, the CHC2 meets current safety requirements (CE marked).

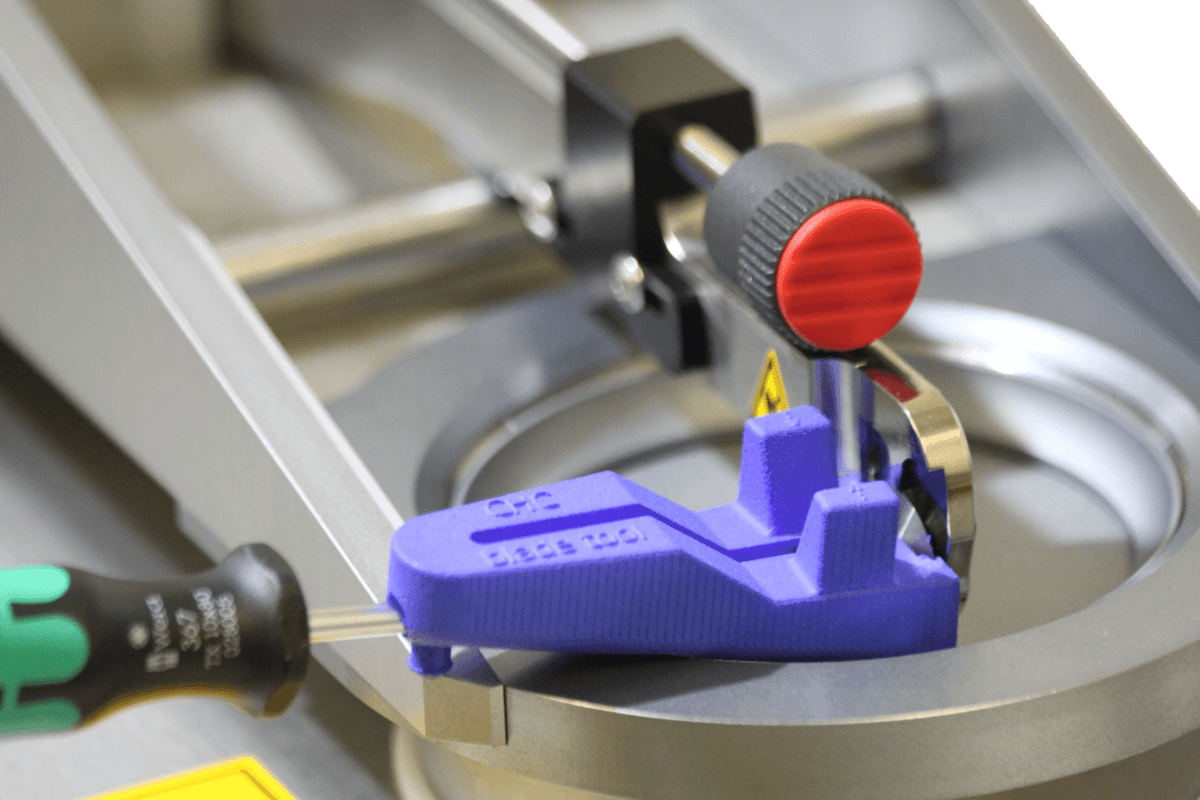

– Changing the cutting blade without touching it, using a special safety tool.

– Automatic safety mode when cover is opened.

Efficient:

– Table top model with small footprint, saves up expensive lab space and is easily transportable.

– Durable carbide blade.

– 18 blade positions visually indicated with laser engraved index marks.

– Low power consumption / energy efficient.

Eliminate operator variations

Customization:

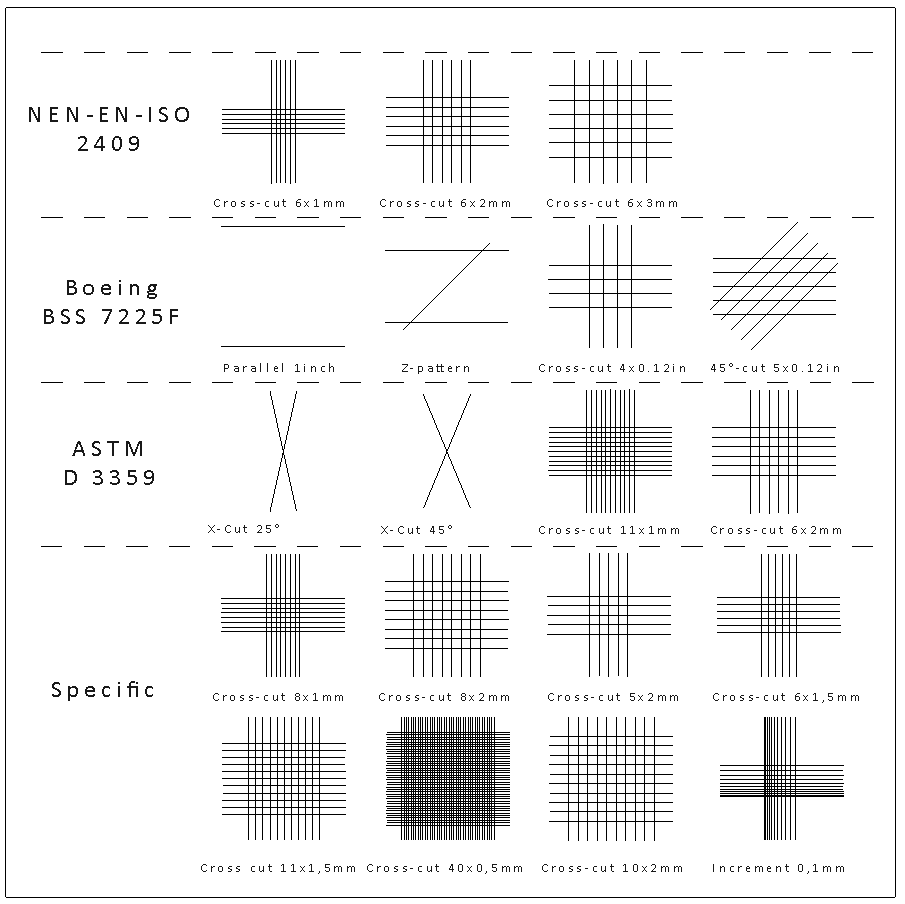

– Quick access to pre-programmed patterns according to various norms (ISO/ASTM/BOEING).

– Additional patterns can be programmed as supplied by customer.

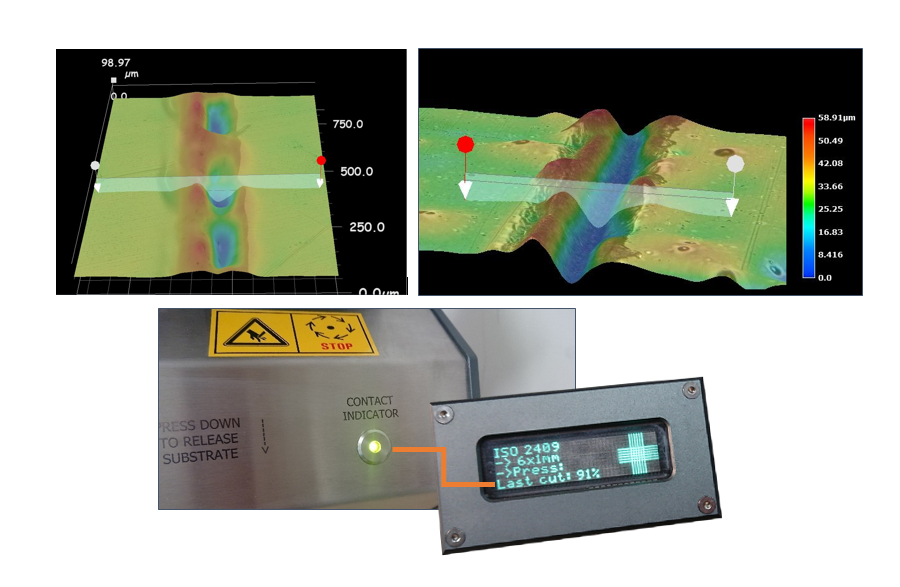

– Contact indicator, which lights up when the blade cuts through the coating.

– Cut-through percentage indicator as an unique feature (optional).

Next level:

– Level up your performance with this professional high-quality equipment.

– Currently the best and most versatile device on the market.

Easy installation:

– Plug & play setup and operation.

– Full package delivery with all required accessories including clearly illustrated English manual and an quick start guide.